Convenience lifts compliance. Compliance lowers risk.

Teamwork is of the essence in foodservice kitchens and other high-priority locations. Team effectiveness calls for equipment that mirrors their personal commitment to frequent handwashing and customer safety. Reliable, quality-driven choices, simply make the right thing easier to do.

Food-handling staff will be washing their hands from 8-24 times per 8-hour shift, depending on the menu, the people served, supervisory leadership, and the owner’s tolerance of risk. Matched modules make it easier for the staff to do the right thing and establish the conditions for sustainable success.

Convenience starts with integrated components, working together for effectiveness and efficiency in a well-lighted, practical location. The optimized hand hygiene station includes a durable deep-draw stainless steel handsink, a reliable touch-free faucet and an invitingly-clean appearance. Touch-free dispensers with ports for future data collection drive the hygiene and process-control factors. User-friendly materials motivate frequent use of soap, sanitizer, paper toweling, gloves and the recyclable nailbrush.

Convenience is also about flexibility. Operators may assign different regimens to better serve those working with higher risk, ready-to-eat foods. This may include the use of a nailbrush or to follow the wash with an application of hand sanitizer, conforming to the well-established sequence of sanitizing after cleaning. Easy-donned single-use gloves may be specified for others.

HFL5000

Handwash Station

Specifications

Plan Review minimums vs. Risk-based specifications

Handwash station specifications are first set by operational goals that summarize the acceptable risk. While the Plan Review is critical to the start of operations, it must not supersede the brand-protecting, risk-based objective.

Kitchen design professionals are increasingly recognizing the strategic value of sustainable diner-defined specifications. Once they are verbalized, understood, numerically established and agreed, specific standards are stipulated. The value of the consultant’s work must first be judged by actual staff handwashing – its effectiveness and efficiency. Frequent use is the goal of the savvy design consultant. Diner-defined designs are best rewarded by added contracts.

Best Practice Consideration

A kitchen plan is a timely convergence of many disciplines to meet a single goal, expressed in a kitchen layout. That single goal is safe food which, in turn, meets all the other operationally distinctive criteria. Good handwashing starts here.

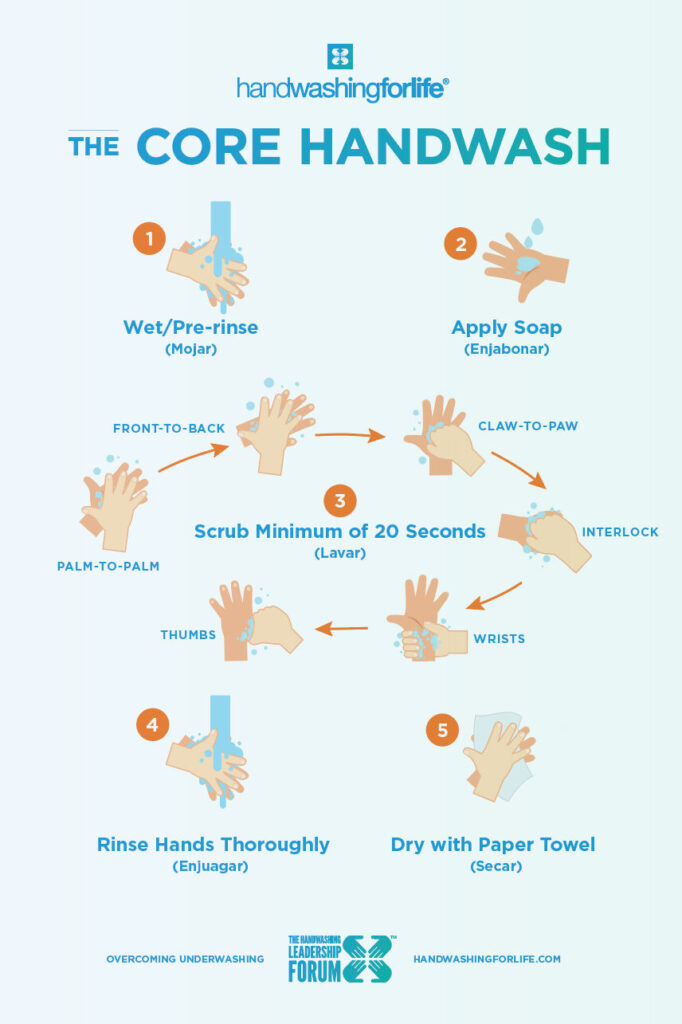

Setting Handwash Station specifications is a process in laying down the conditions for success. It is an exercise best conducted within the context of the 5 step HandsOn protocol. It is largely within Step 3: Optimize, that ensures the Conditions for Success are in place before training. If compliance isn’t convenient and isn’t user friendly, it isn’t done.

A durable deep draw handsink with a nailbrush bracket opens the spec list. A bacteriostatic coating option gives the station a sparkling clean factor, encouraging its frequent use. The most reliable touch-free faucet is added along with its self-generating power module. Next comes the touch-free paper towel, soap and sanitizer dispensers. The latter two include on-board communication ports to add electronic monitoring technologies. Easy-don gloves complete the list. Here is a visual equipment tour: http://handwashingforlife.com/handsonsystem

Dealers specifying the Eagle HFL-5000 are requested to contact Handwashing For Life to secure a package of ancillary resources for their client. It includes implementation advice, two downloadable posters, and a free copy of the award-winning, language-free video training series – The Why, The When & The How.

Handsink

Select a deep draw, positive drain stainless steel bowl to:

- Maximize water saving

- Provide no-splash washing/rinsing of hands and

- For faster drying of the bowl surface, eliminating a potential germ harbor. Consider an anti-microbial coating for more effective cleaning.

Note: “Brushless Carwash” type automatic handwash systems lack the hand-to-hand friction necessary for a good cleaning. They are acceptable where light-duty cleaning is specified.

Touch-Free Faucet

Reliability is the hallmark of electronic faucets with dual sensors. A 2.0 GPM flow is needed for speed of effective washing and rinsing. Matched with a deep draw handsink, this saves nearly a gallon of heated water with each wash.

A battery-saving “turbine” can be installed in the water line to generates the power to operate an electronic faucet, creating a new standard in reliability and avoiding costly electric line drops.

Handsoap

Criterion #1 is effective removal of the principal pathogens responsible for foodborne illness. Direct costs of soap by the liter vary widely. The best choice is the one that never runs out of user-friendly soap, that provides staff motivation to wash frequently, that saves operational time (wash and rinse) and reduces employee absenteeism.

A closed cartridge/bag system enable formulating a truly skin-friendly product, avoiding harsh preservatives. Touch-free dispensing adds to the hygiene factor. A “Power-on-the-Refill” feature saves battery changing time.

Avoid germ-harboring refillables at all costs as they are nearly impossible to clean once contaminated.

“Smart” soap and sanitizer dispensers include a port to align with third-party software systems that track compliance by team or individual, providing process control which dramatically increases compliance.

Nailbrush

Often nail brushes harbor more microbes and pathogens than any other appliance in the kitchen. Dispose of high-risk brushes (wooden based, glued or stapled bristles) and replace with fused-bristle brushes. Run through the dishwasher or power soak to recycle.

Paper Towel

Select single-use paper towels that deliver one sheet drying results, without touching germ-laden levers, buttons or dials. Eliminate all blow dryer systems from employee handwash stations. Research has demonstrated hot air drying is counter good hand hygiene practices. Look for jam-free, measured dispensing with ease of roll changes to simplify maintenance.

Hand Sanitizer

Add hand sanitizer dispensers that match the specified soap units (see above). A post-wash application of alcohol-based hand sanitizer adds a level of confidence that hands are ServeReady®.

Single-Use Gloves

Quality, single-use gloves deliver an added level of protection against foodborne outbreaks and provide a visual cue to customers that the establishment cares about their well-being. Waste in terms of lost donning time and “multi-pull” losses can be answered with a single-glove dispenser.

Posters

The Core Handwash

The Core Handwash focuses on a professional technique as an option to the “sing happy birthday twice” directive.

Learn The Core Handwash »

Why, When & How Training Video

Get full copy of HandwashingforLife’s Why, When & How Foodservice Training Videos. These videos are fast-paced, language-free video 5 minutes in length with 3 modules developed for training the Why, When, and How of hand washing. An excellent tool for motivating good hand hygiene behavior with existing and new employees.

How to Glove

Add Monitoring Capabilities

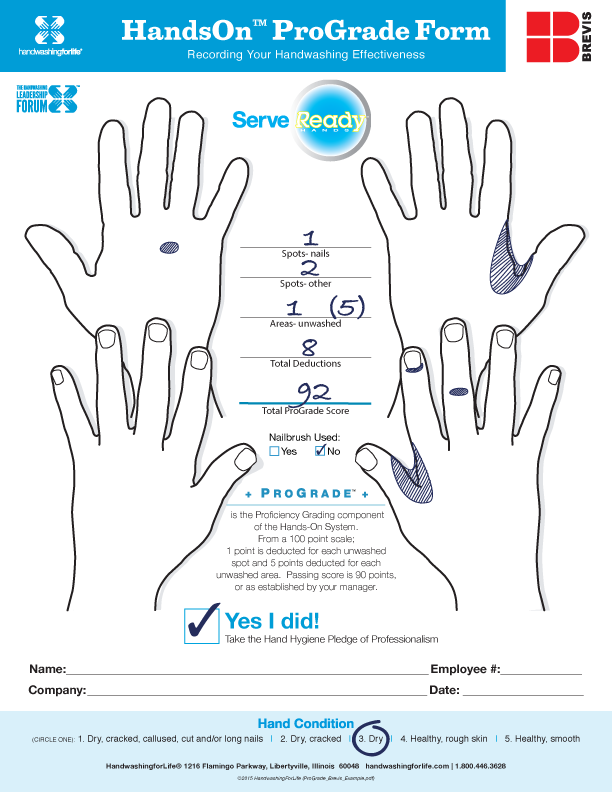

Handwashing must be a defined process with numeric measurement and standards. It is the data from this approach that drives sustainable compliance. Data motivates better handwashing behaviors.

Monitoring Technology

Monitoring technologies are available to track compliance by team or individual. Tracking by name demonstrates the greatest gains. Identification can be achieved by entering a code or by voice recognition. Badged options are accepted in Healthcare kitchens but are an issue in foodservice because of high staff turnover and the need to have a badge management system.

Score Keeping

Food prep and wait staff are accountable for meeting handwashing standards and related policy requirements. This is a measure of their professionalism and condition of employment. Electronic handwash reporting makes it easy to provide staff with their scores in real-time, without the need to keep time-wasting manual performance logs. A timely personal “corrective action” is totally aligned with a basic HACCP principle.

A professional handwasher also requires a periodic confirmation of their skills in handwashing. The ProGrade™ system provides the process and templates.

Have HFL5000

specified from the start!

All too often hand hygiene stations are cobbled together as the parade of salespersons learn of the installation. Few know anything beyond the miracles of what they sell. The best pitch wins.

A contrasting approach is to tap into the knowledge base of your Consultant Specifier who understands that the choices are first about managing risk and setting up the conditions for success. The hand hygiene station must be effective, convenient, and reliable. Then it will be used.

Secondary benefits will be generated by the integration factor and long-term savings. The cheaper flat bottomed handsink gives way to a splash-free combination of a deep-draw sink and faucet choice. All dispensers, from water to soap and paper towels, are touch-free. The nailbrush has a custom drying hook and gloves are safely dispensed, one at a time.