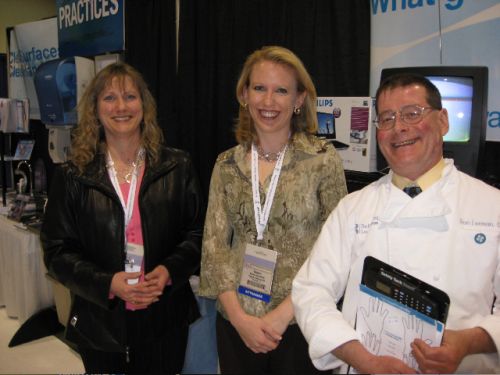

The Handwashing For Life® Olympics staged in Washington DC Held in conjunction with the 10th annual Food Safety & Security Summit, this year’s venue was visited by two former title holders, both multiple winners. From the left are Michele Samarya-Timm from the Franklin New Jersey Health Department and Kristen Machicek from Pappas Restaurants, better known […]

Handwashing: Management Basics Win Again

Using the management skills we have to get the compliance we don’t have. Financial risks for those serving food increase sharply where hand hygiene is not a senior management priority. Neither training nor science creates sustainable gains in handwashing compliance. That takes a management reporting system. Start with a Team Risk Assessment Standards are needed […]

Earned Scheduled Inspections

Scheduled inspections convert the kitchen atmosphere from one of a raid to a classroom. Which is the better environment for transferring sustainable food safety knowledge and motivation? Olmsted County (Rochester MN) has experienced many of the benefits regarding scheduled inspections since they started their award winning (Crumbine Award) program in 2001. One of the key […]

Minimize Prescriptive Code Writing

Handwashing has few standards because there is no specification for a clean hand. Soil has no standards because it varies so widely and so little is known about soil adhesion to human skin and its transfer profile. Operators have to sift through the grey science and determine what black-and-white regimens will be used as they […]

Handsinks Located for Compliance

Kitchen consultants/designers focus on providing the operator with a minimum of handsinks based on often creative interpretations of local codes. Their reason? Even the minimums are underused. Why put more in and reduce productive space? The Plan Review process continues the focus on minimums rather than worker convenience and compliance. Can the Model Food Code […]

The Handwashing Log

Decision making is commonly supported by information regarding performance versus standards. In managing handwashing there are few standards and little documention to guide improvements. Senior management is not asking for it hence few take handwashing seriously.What gets measured gets done. Operators in Maricopa County (Phoenix AZ) are offered incentives if they can demonstrate they have […]

Ill Customer Advisory

Can the Model Food Code help encourage ill customers to stay home and encourage operators to deploy customer oriented interventions similar to those deployed by the cruise industry, recommended by the CDC. The more we learn more about the asymptomatic nature of norovirus and hep A, the more likely we are to see outbreaks linking […]

Air Dryer Limitations

How can the Model Food Code Annex be used to alert kitchen designers and consultants of the limitations of air dryers in foodservice, in both the kitchen and restrooms? Biofilms on the hands require the friction added by single-use paper towels. Air dryers lose the log 1 reduction of pathogens attributable to the use of […]

Surface Cleanliness ATP Monitoring

Cleaner sufaces protect hand cleanliness whether hands are bare or gloved. Could the Annex of the Model Food Code be used to raise awareness of ATP technology as a rapid detection method for training, verifying and monitoring surface cleaning procedures. These documented numbers can become part of self-audits as well as third-party auditing reports. Surfaces […]

Log 3, 4, 5 Handwashing Procedure

Handwashing effectiveness is commonly measured by log reduction. It is considered to be limited to a log 2 reduction by authors of the Model Food Code. Log 3, log 4 and log 5 reductions may be available by using these integrated best practices: Wet/Pre-rinse hands in a stream of warm water flowing at a rminimum […]