The OurWIN™- MyWIN™ commitment methodology helps set handwash frequency standards, verified by team or individual compliance systems.

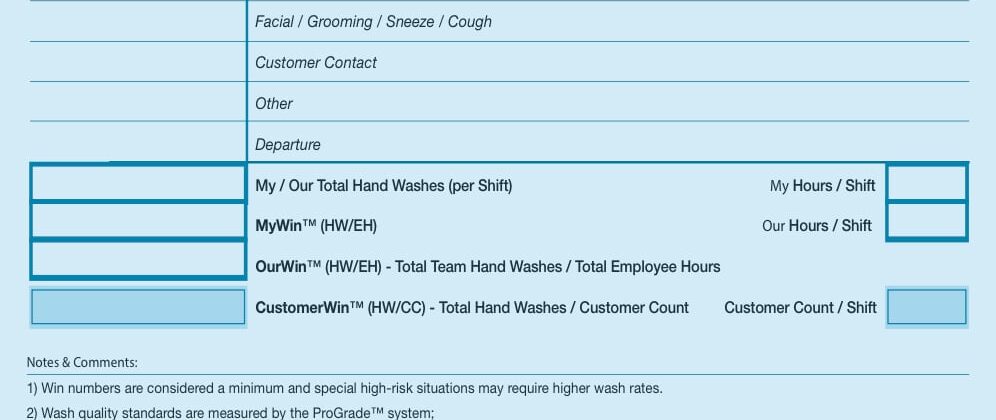

Foodservice team members are trained individually but also to work together in caring for the people they serve. Each must understand and commit to an appropriate and accountable handwash frequency which Handwashing For Life® calls their MyWIN – my Wash Index Number. Individual numbers are added up to yield the OurWIN, the team’s Wash Index Number.

Electronic monitoring systems provide the feedback with their compliance levels via a realtime scoreboard or a readily available dashboard. This adds the motivation of professionalism, competition and success. It’s the operator’s choice to motivate behavior change individually or by team.

- Accurate, realtime data by handsink, by shift, by unit, by team, by location, by enterprise and in some cases by individual

- Operationally customized reporting

- Electronically docks with leading hand soap dispensers

- Includes HACCP-Hands Realtime Scoreboard feature as an option

- Tailored to the individual operation via the OurWin – MyWIN standards exercise

- Both OurWIN and MyWin checklists provide a basis to collaboratively set, agree and commit to frequecy standards.

The MyWIN™ Individual Hand Wash Monitoring System

This option adds the knowledge of who is washing where and when. It is preferred by some as a way to see that training is targeted and effective. It is particularly helpful in the onboarding of new employees. For some systems, this adds a badge management factor to the implementation. Another technology uses voice recognition to gather data on an individual basis. Individual privacy and data security are required in some environments, especially in labor union situations.

The MyWIN version proves the individual’s commitment, competence, and may help supervisors recognize their success in the Performance Review process. Data can be grouped into teams by shift or area of responsibility, opening up the utility of the HACCP-Hands Scoreboard for their direct feedback on handwashing frequency. It adds the motivation for professionalism, competition, and success.

Handwashing For Life has witnessed the truth in this adage, What gets measured gets done and has authored this variant, What gets rewarded gets done…BETTER, FASTER & CHEAPER.

Restaurants generally know their handwashing frequency is low but now it is by choice. New wireless technologies take handwashing from an out-of-control foodborne illness random intervention to one of professionalism and customer care, eliminating the customer-care deficit.

Restaurants have choices to matchup technologies with their corporate culture.

Futher information is available from:

- Handwashing For Life, Jim Mann, 1-847-918-0254

- Clean Hands, Ray Johnson, 1-314-662-0451

- CloudClean, Dexter Jasper, 1-800-627-6368

- SmartLink Dispensers (GOJO), Tamara Cross, 1-800-321-9647

Getting started:

- Assess the risk of the under-washed hand.

- Set and agree on preliminary Dry-Lab standards (QA, Operations, Risk Management) in keeping with corporate policies. http://handwashingforlife.com/blog/jim-mann/myq-self-monitoring-hand-surface-hygiene

- Identify 1-3 average restaurant/s and install one of the above tracking systems to determine the current baseline.

- Look closely at the advantages of the two different approaches and their matching technologies:

- The Team Monitoring choice offers the advantages of cost, easy start-up, and focuses on food safety as a team event. It avoids privacy issues sometimes raised by lawyers and unions. Gross handwash counts can be reported by shift or by time. These results can be displayed in realtime on back-of-house monitors, helping self-motivate corrective actions (per HACCP), compliance standards, and teamsmanship. The data can be dumped at the end of each day for those operators concerned with potential legal exposure.

All the offerings can be upgraded to individual monitoring without obsoleting the original Team equipment. - Individual Monitoring helps focus training and more directly can connect with performance review systems where good behaviors are rewarded and poor compliance can be disciplined. This choice also has a direct staff-feedback monitor option described above. Information gathered on individual handwashing behavior can be grouped into teams via customized reports.

- The Team Monitoring choice offers the advantages of cost, easy start-up, and focuses on food safety as a team event. It avoids privacy issues sometimes raised by lawyers and unions. Gross handwash counts can be reported by shift or by time. These results can be displayed in realtime on back-of-house monitors, helping self-motivate corrective actions (per HACCP), compliance standards, and teamsmanship. The data can be dumped at the end of each day for those operators concerned with potential legal exposure.

- Reset desired standards, tailor reporting to include Operations and Risk Management along with Quality Assurance. Roll out the program within the bounds of control and sustainability.

Celebrate each step of improvement and successful maintenance of the new standards, a prime indicator that the customer-centric culture is working.

Numbers help establish and sustain process control and provide a framework for measuing handwashing compliance. Regular feedback motivates both staff and management. Success is celebrated and maintained. Variations from the norm are swiftly corrected and the risk of a foodborne outbreak drops. The business and its jobs are secure. The public’s perception of quality in both the place and the people keep them coming back.

These are the primary outcomes of the HandsOn System.

Stepping down the risk by stepping up monitoring technologies

Culture change is the only way we have found to enhance time-hardened handwashing behaviors. Years of accepting low compliance now define today’s reality. Whatcha got is … who you are!

Years of training have produced waves of temporary peaks in performance. Training without standards has proven to be both frustrating and costly as gains slip back to the undeclared norm.

Do you really want to change? From where you are on the organization chart, can you build a leadership team to get it done? The HandsOn™ System is designed to help chart this strategic move for the leaders who respond affirmatively.

Some chains have managed this culture change from one of production first to customer safety first at a unit level, usually capitalizing on the very special leadership characteristics of an individual manager. Handwashing For Life recommends each chain restaurant concept search out such a unit and develop a repeatable process model around it. Franchisees have even more incentive to lower the risk of a potentially business-ending outbreak.

This prototype facility can provide data to better value the risk of current corporate hand hygiene behaviors and determine the risk-based costs for a sustainable solution. Can it be done without raising prices? Continued nurturing can hothouse the initiative for months or years while resources are defined, acquired and aligned for rollout. Can cleanliness be a differentiator and business builder?

Monitoring, step five of the HandsOn System, is first and foremost about staff motivation. It is already a part of every foodservice operation. Informal observation by supervisory staff is the standard and in general, has proven to be inadequate. Electronic “observations” multiply the information to statistically significant levels to facilitate better management decisions.

Handwashing’s Guide to Monitoring Options

Poor hand hygiene remains the number one contributing factor identified in outbreak investigations. New monitoring technologies, “electronic observation”, warrant a reassessment of handwashing and process control options. Accurate data is now available for those that believe better handwashing can significantly lower their risk of an outbreak..

The ServeReady® Hands Priority – Motivated, Measured & Managed

Changing hand hygiene behaviors is a reset of priorities where customer safety rises to the top of the list of restaurant services. Safety sets the intuitive compass for action and becomes the default as each employee is reprogrammed for the day’s menu and priorities. Reaching and sustaining handwashing frequency trumps the traditionally measured efficiency factors.

The HandsOn System provides the structure to leverage these new technologies to change behaviors from management to prep line workers and wait staff. It can help get started by setting up a collaborative assessment of current policies and practices to be sure all potential hurdles are addressed in The 5 Handwashing Hurdles discussion.

New monitoring technologies add process sustainability.