Standards provide the language for inter-departmental collaboration in agreeing on the goals for training as well as customer and brand protection. This step translates the management’s tolerance for risk into traceable performance numbers.

Start With An Approximation

Rutger’s food safety risk authority, Dr. Don Schaffner, reacts to the approximation strategy in opening the door to a risk-based sustainable handwashing process:

Restaurants make few important decisions without numbers, without standards, without goals. Yet for hand hygiene, there are virtually no standards and no meaningful reporting. Food handlers are trained to wash but not to a standard. They are asked to wash often, but again without even a range of handwashes expected for a shift. Nor are there standards for the surfaces that most likely are contaminating clean hands.

The “Selector” curve first captures the experience of the persons most knowledgable about the operation. They post their vote for likely current handwashing rates and a level for where they want to be. Then actual frequencies are then captured, preferably using technologies listed in the Commit & Comply matrix. Safe levels attained? If yes, relax and celebrate! Shortfalls? Get the team together and consider conducting a separate hand hygiene audit.

Commit & Comply

Setting standards for quality and frequency goes a long way in changing behaviors and sustaining the improvements. Before starting this phase, refer back to Step One of the HandsOn System to seek agreement on the risk of potentially low compliance. Commitment to action paves the way to success. Measurements can motivate. The HandsOn System guides their implementation and protects the process.

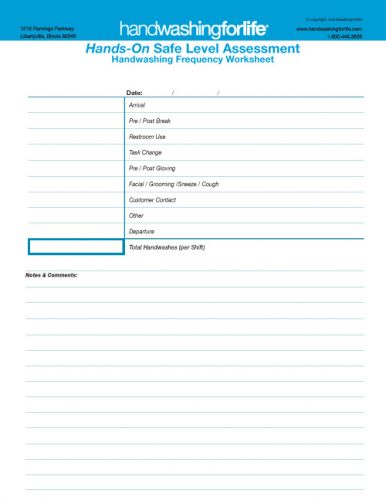

Initial Frequency Assessment Worksheet

HandsOn™ Handwashing Frequency Assessment for Individuals

HandsOn™ Handwashing Frequency Assessment for Group Shifts

HandsOn™ Setting Never-Fail Safe Levels Worksheet